Production Facility (Gravure Printing Cylinders)

Production Facility (Gravure Printing Cylinders)

Uflex Cylinder Business has Production Facilities in India & Overseas:

- Noida, Uttar Pradesh, India

- Jammu, J&K, India

- Jebel Ali Free Zone, United Arab Emirates

- Cairo, Egypt

- Nairobi, Kenya

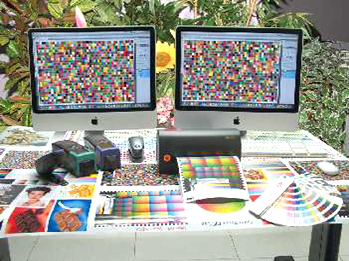

1) In house designing:

In-house “CREATIVE Team…..

We offer oOne stop solution from Design to Print – traversing the complete life-cycle.

A dedicated team of designers does an exceptionally creative job with immaculate finesse. We create designs for all kinds of Stock Keeping Units (SKUs).

2) Pre-press:

Uflex Digital Pre-press Department uses a specialized packaging and planning software

ARTPRO & Pac Z to meet Gravure & Flexo printing requirements. The

software is the last word in techniques like color separation, trapping, bar code generation and pantone. Highly experienced and internationally trained professionals spin their magic

on color calibrated monitors for optimum halftone results. Besides this, exclusive soft-wares are

deployed for making wall papers, wood grain and texture design cylinders. To get vibrant and

rich colors, Hexa-chrome technology is put in use. The digital file finally gets ready to be

engraved on the cylinder. Most importantly, in order to maintain the confidentiality of the job,

our State-of-the-art ERP solution makes sure to safeguard all the interests of our esteemed

customers.

Prepress Features:-

GMG Color Management....

- Software helps to create color calibrated prints with engraving to match final printing results.

- Output data of Dot gain / Dot lost is stored as a reference from proofing and printing machines.

- 50% reduction in Test Proofing Activity.

Prepress Output on Actual Substrate

- The output on actual packaging substrate helps closest validation of colors for shade approval.

- Time & Cost saving management.

- The output will be at your door step in 24-48 hours.

3) Cylinder Manufacturing Facilities:

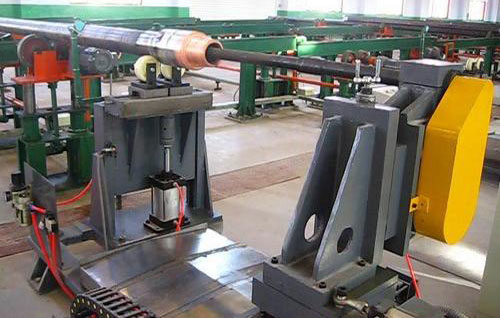

a) In-house base shell manufacturing

- Accuracy up to 10 microns/ meter.

- CNC Machines, Inner Bore Making Machine, Cone & Flange making Machine, High Accuracy Grinding machine, Auto Wielding Machine etc.

- This ensures Dynamic Balancing for achieving line speed up to 500 m / min.

- Speed to market: Design to Dispatch – all in 4 working days.

Inner Bore Making Machine

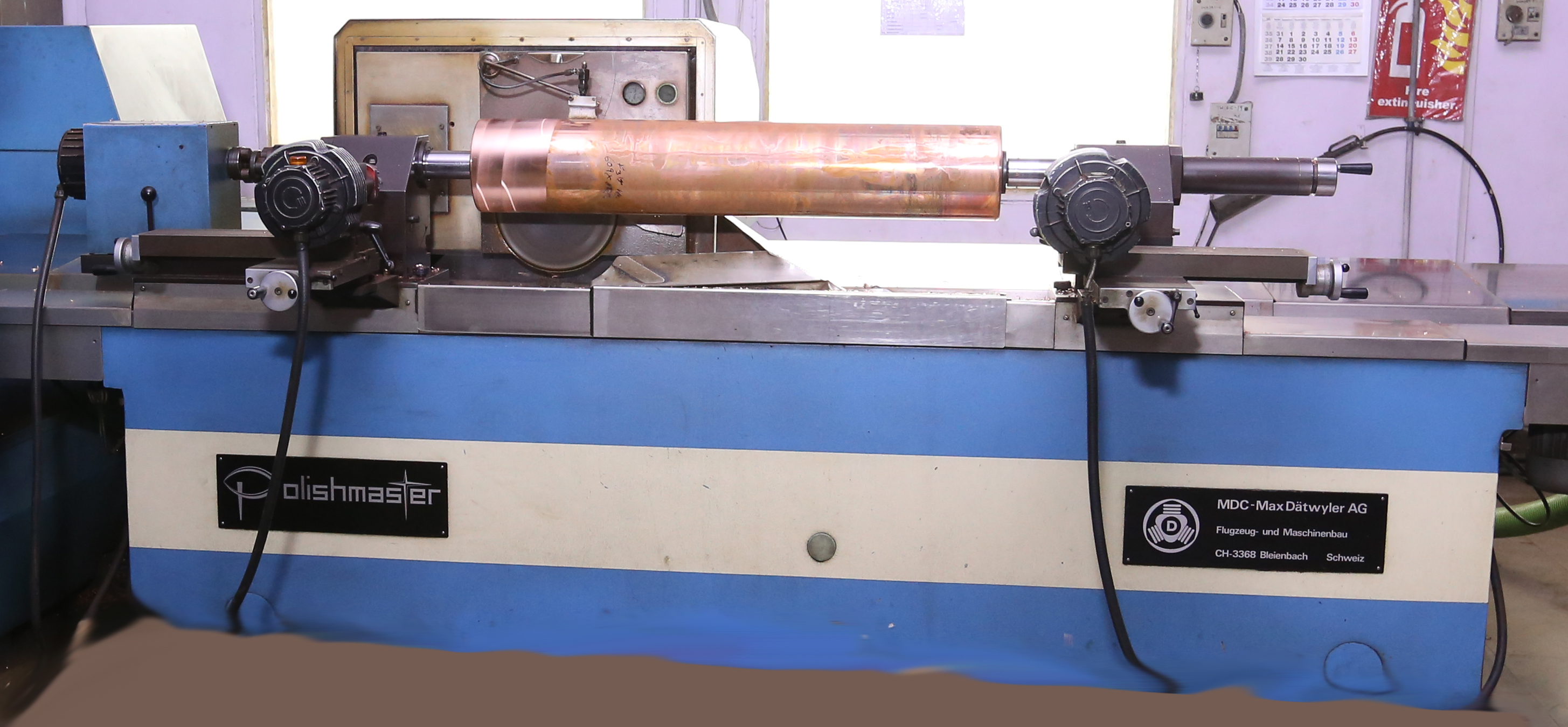

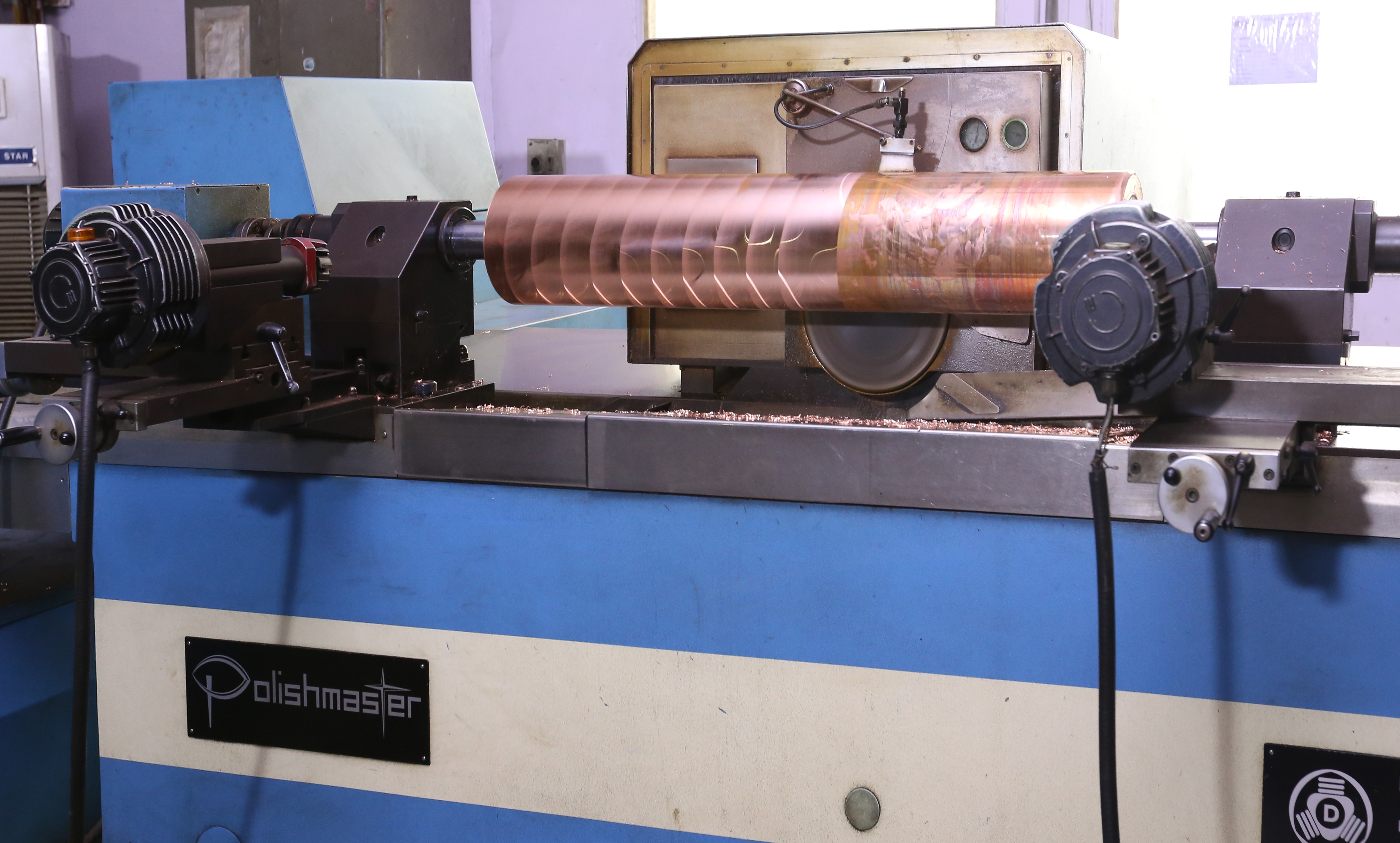

b) Fully automatic plating line from trusted suppliers

- De-chrome

- De-greasing

- Nickel Plating

- Copper Plating

- Chrome Plating

- Chrome Polishing

A high precision digitally controlled MDC Daetwyler "Polish master machine" with an accuracy of 10 microns per

meter is used to achieve accurate and mirror surface that is required for electronic engraving on the cylinder.

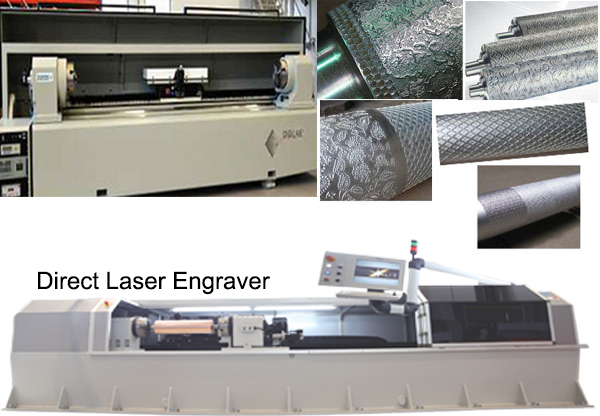

d) Engraving

Electronic Engraving:

Mega depth up to 80-100 microns can be engraved.

Extreme Head & Transcribe Head Technology for sharper / micro text.

Laser Engraving:

Apart from existing 12 electronic engraving lines, A State of the art Schepers

LASER has been added at our manufacturing site at Noida.

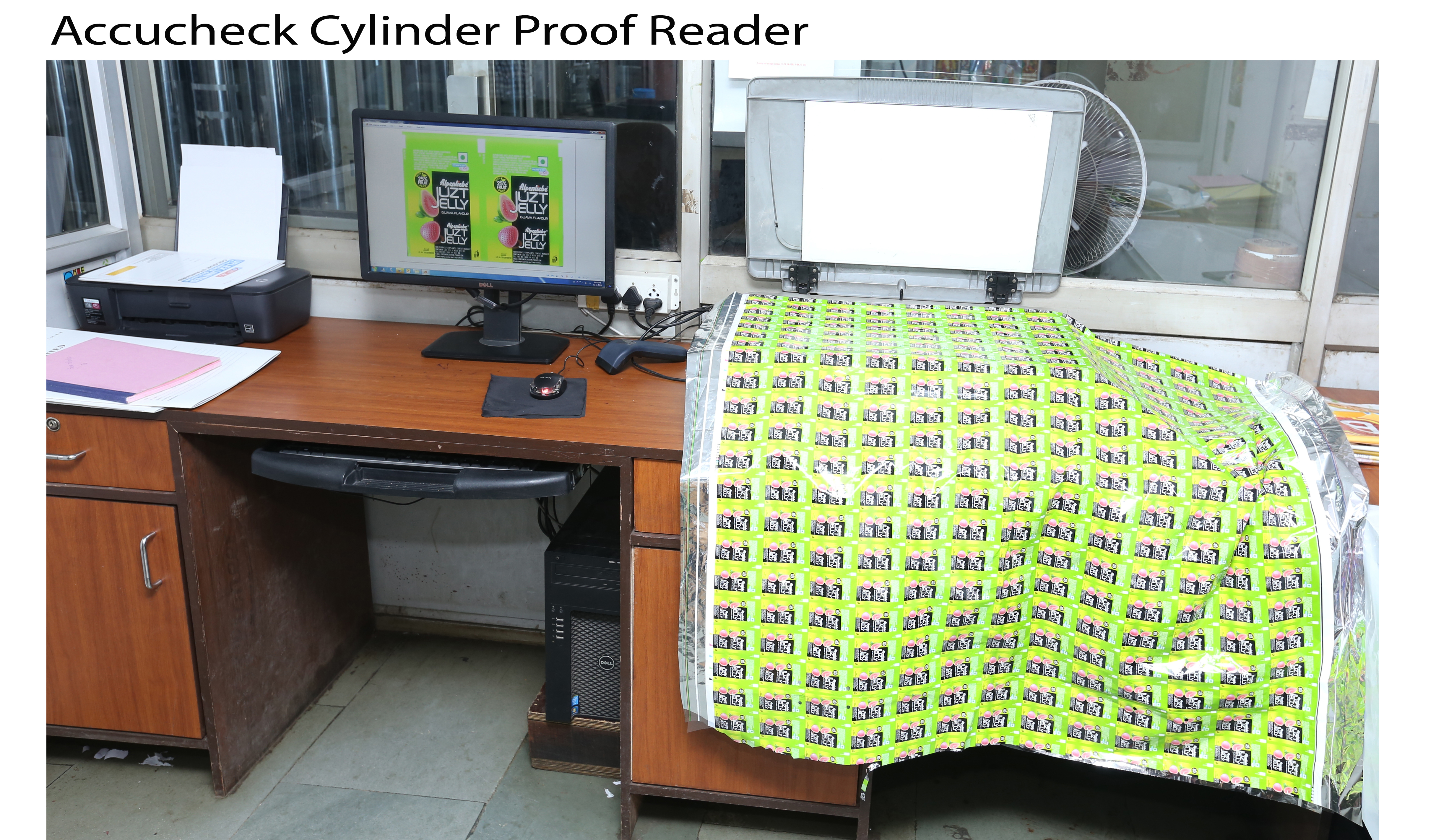

e) Cylinder Proofing

All the manufactured cylinders are proofed to cross check the process parameters and also to

validate output synchronization amongst Pre-press, Engraving machine and Printing

machine…..so we ensure “whatever we proof replicates in print…”

Accucheck proof reader:-

The unique proof reading process make ensures the errorless and efficient, proof

checking.

The actual proof on substrate is scanned and superimposed on soft file of the

approved design. Any deviation can be easily detected by this

customized software.

f) Quality Checks

QC at each and every stage of the process:-

- Chemical analysis of plating bath on daily basis.

- Standardized engraving parameters.

- Cylinder quality analysis.

- Proof reading, shade matching as per customer requirement; checking for Delta E and LAB values of colors, Barcode verification & reporting.